Welcome to Shenzhen Bondao Technology Co., Ltd.

Elevating Metal Component Manufacturing: The Cold Heading Advantage

In the realm of metal component manufacturing, the cold heading process stands as a hallmark of precision engineering and efficiency. At Bondao, we pride ourselves on our expertise in this advanced manufacturing technique, delivering superior quality and reliability to our clients worldwide.

Understanding Cold Heading Process

Cold heading is a specialized metalworking process used to form metal blanks into desired shapes and sizes using cold deformation techniques. Unlike traditional machining methods that involve removing material, cold heading involves reshaping metal through compression, ensuring minimal material waste and superior dimensional accuracy.

Product Features and Advantages

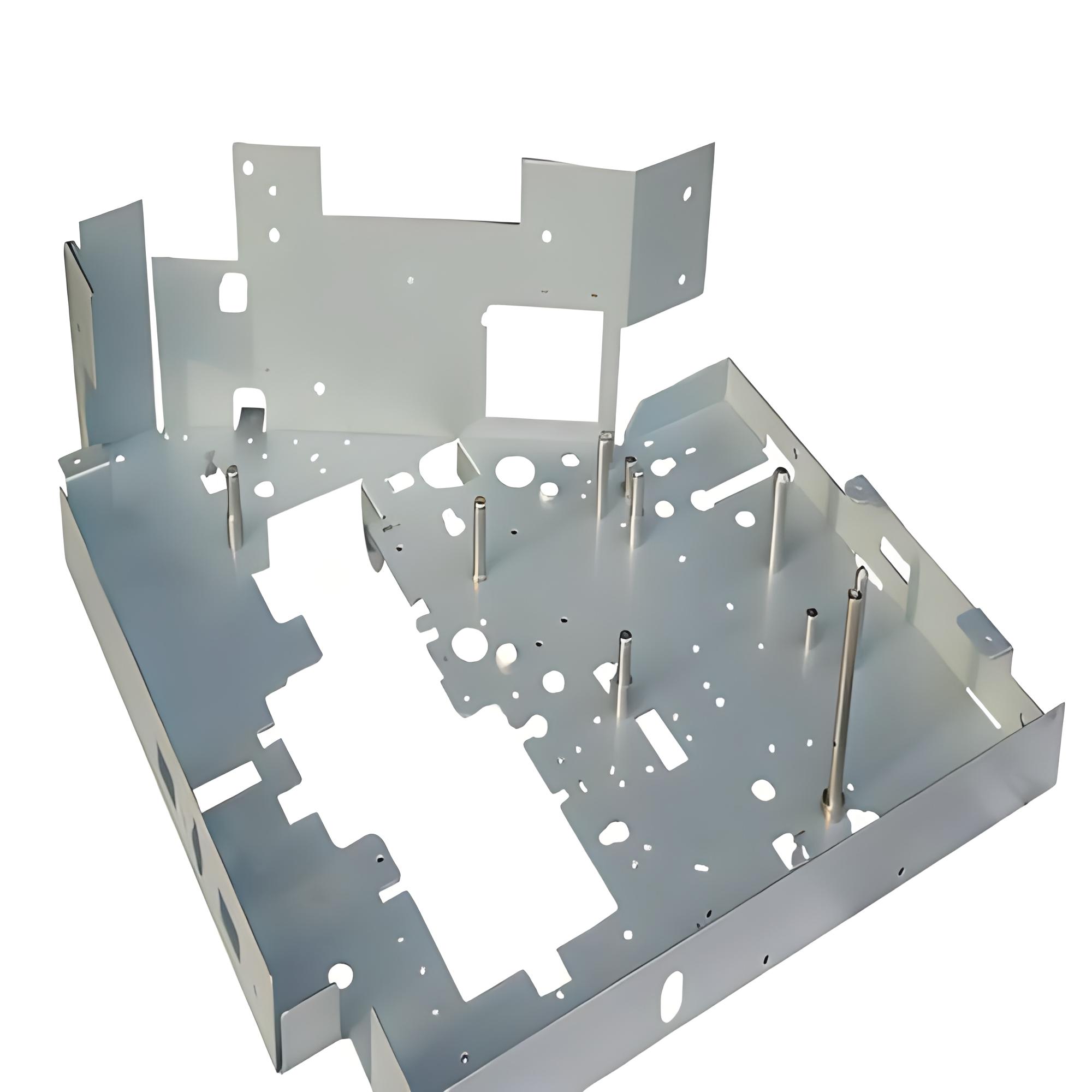

Precision Engineering: Cold heading allows for the production of complex geometries and intricate designs with unparalleled precision, making it ideal for the manufacturing of fasteners, screws, bolts, and other critical components.

Material Efficiency: By utilizing cold deformation, cold heading minimizes material waste, resulting in cost-effective production and sustainable manufacturing practices.

Enhanced Mechanical Properties: The cold heading process improves the mechanical properties of metal components, including increased tensile strength, improved fatigue resistance, and enhanced surface finish, ensuring superior performance and longevity in diverse applications.

High Production Efficiency: Cold heading offers rapid production cycles and high output volumes, making it suitable for both small-scale production runs and large-scale manufacturing operations.

Our Competitive Advantages in Cold Heading Process

As an industry-leading manufacturing facility with extensive experience in metal component fabrication, we possess several key advantages in the cold heading process:

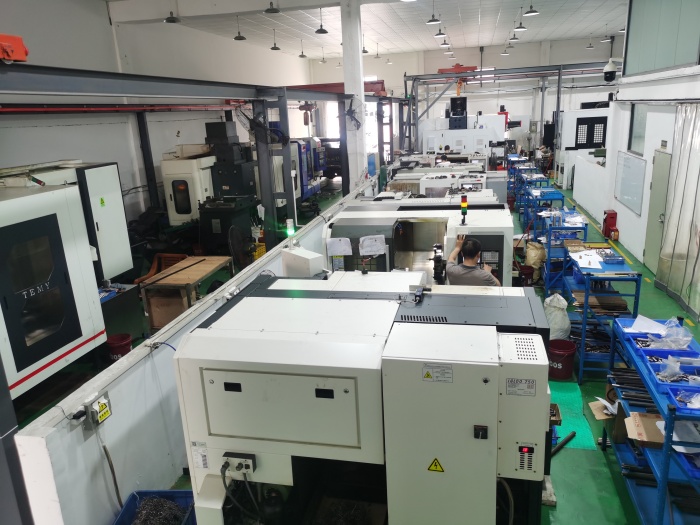

Advanced Machinery and Technology: Equipped with state-of-the-art cold heading machines and cutting-edge technology, we ensure precise control over process parameters, resulting in consistent product quality and dimensional accuracy.

Skilled Craftsmanship and Expertise: Our team of highly skilled engineers and technicians boasts decades of experience in cold heading and metalworking, enabling us to tackle complex projects and deliver innovative solutions to our clients.

Quality Assurance and Compliance: Committed to the highest standards of quality and compliance, we adhere to rigorous quality control protocols and industry regulations throughout the manufacturing process, ensuring that each component meets or exceeds customer expectations.

Customization and Flexibility: Recognizing the diverse needs of our clients, we offer customizable solutions tailored to specific requirements, including material selection, surface treatments, and geometrical specifications, providing unparalleled flexibility and versatility in product design.

At Bondao, we are dedicated to delivering excellence in every aspect of the cold heading process. From precision engineering to superior product features, we strive to exceed customer expectations and set new benchmarks for quality and innovation in the metal component manufacturing industry.

Contact us now to learn more about our cold heading capabilities.