Welcome to Shenzhen Bondao Technology Co., Ltd.

BMX Bike Parts: Crafting Quality Metal Components for the Ultimate Ride

At Bondao Technology, we pride ourselves on producing high-quality metal components that are essential for the construction and performance of BMX bikes. BMX biking, a sport that demands precision, durability, and strength, relies heavily on the quality of its parts. In this blog, we will explore some of the key metal components used in BMX bikes and how our expertise in metalworking ensures that these parts meet the rigorous demands of BMX enthusiasts.

The Core Components of BMX Bikes

1. Frames

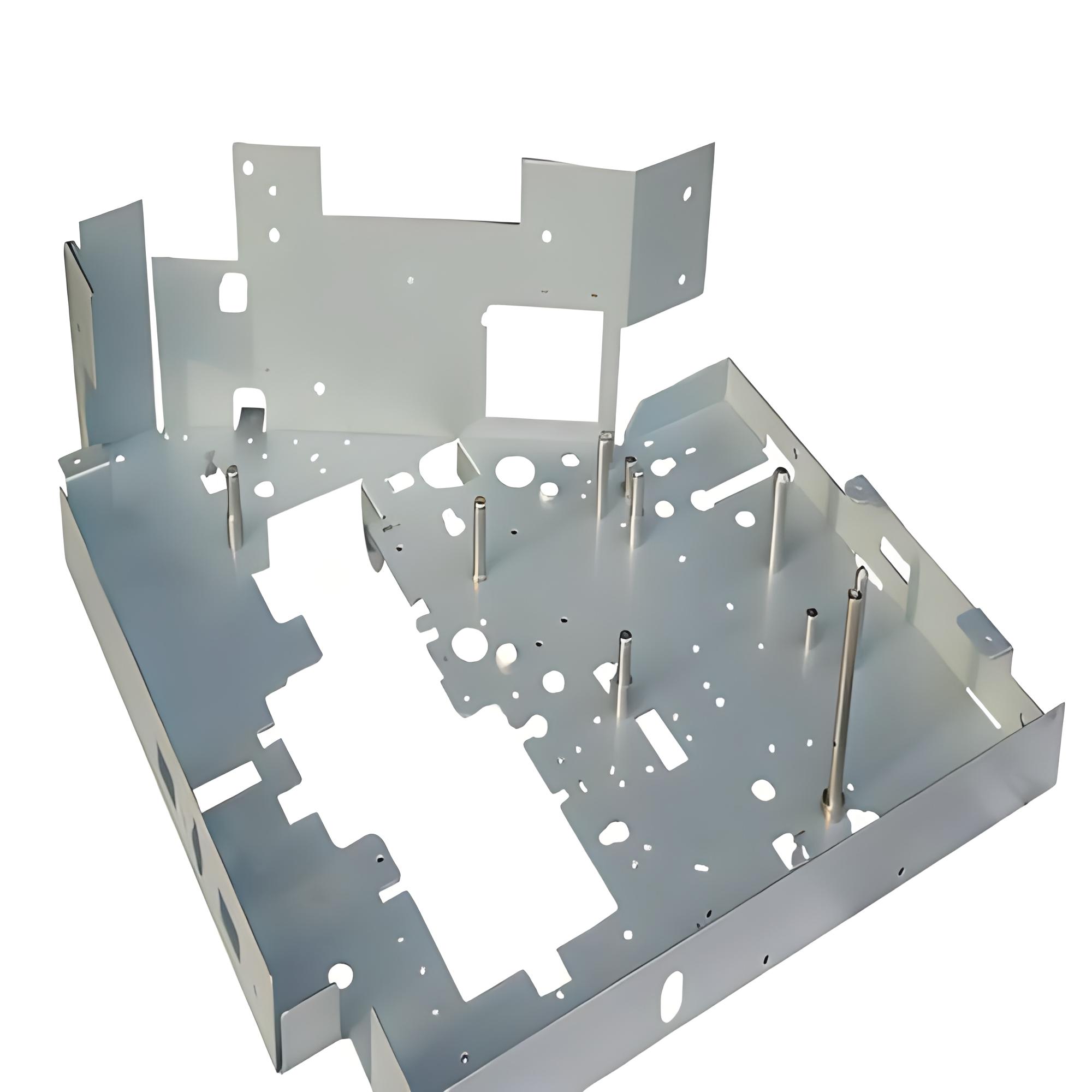

The frame is the backbone of any BMX bike. Typically made from materials like chromoly steel or aluminum, BMX frames need to be lightweight yet incredibly strong to withstand the high-impact jumps and tricks. At Bondao Technology, we use advanced welding techniques and precision machining to produce frames that offer the perfect balance of strength and weight. Our frames undergo rigorous testing to ensure they can handle the stresses of BMX riding without compromising performance.

2. Forks

The forks are another critical component, connecting the front wheel to the frame and allowing for steering control. Just like the frames, forks need to be robust and lightweight. We manufacture forks using high-grade steel and employ meticulous machining processes to ensure they have the durability needed for BMX activities. Our quality control measures ensure that each fork meets strict performance standards.

3. Handlebars

Handlebars play a crucial role in the control and maneuverability of the bike. They are typically made from steel or aluminum and require precise bending and welding to achieve the correct shape and strength. Our expertise in metal bending and welding allows us to create handlebars that provide excellent grip and stability, essential for performing tricks and stunts.

4. Cranks

Cranks convert the rider’s pedaling motion into the rotational force that drives the bike forward. They need to be exceptionally strong to handle the intense pressure and torque generated during BMX riding. We use CNC machining to produce cranks with precise dimensions and optimal strength, ensuring they can withstand heavy use without bending or breaking.

5. Pegs

Pegs are used by riders to perform various tricks and stunts. Made from durable metals such as steel or aluminum, pegs must be both tough and lightweight. Our manufacturing process involves high-precision cutting and finishing to produce pegs that can endure the grinding and impacts common in BMX riding.

Our Commitment to Quality

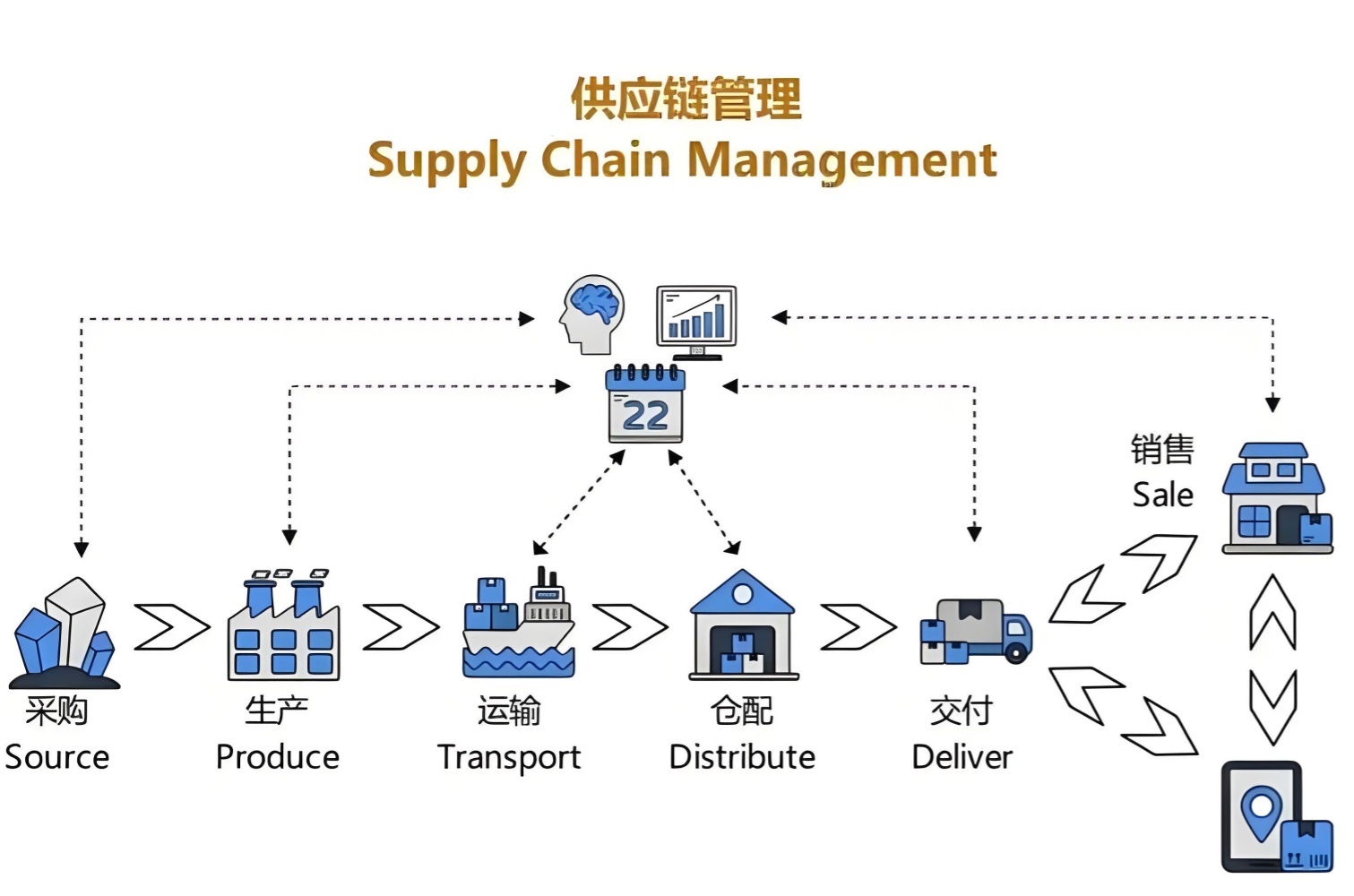

At Bondao Technology, our commitment to quality is unwavering. We understand that BMX riders demand parts that not only perform exceptionally but also have a long lifespan. Our manufacturing process includes:

Material Selection: We choose only the highest-quality metals that offer the best combination of strength and weight.

Advanced Manufacturing Techniques: Using state-of-the-art CNC machining, welding, and bending techniques, we ensure each part meets exact specifications.

Rigorous Testing: Each component undergoes thorough testing to ensure it can withstand the demands of BMX riding.

Custom Solutions: We offer custom manufacturing solutions to meet the specific needs of our clients, ensuring that each BMX part is tailored for optimal performance.

Why Choose Bondao Technology?

Choosing Bondao Technology means partnering with a company that understands the intricacies of BMX bike construction. Our experience in metalworking and dedication to quality ensures that every part we produce enhances the performance and reliability of BMX bikes. Whether you are a professional rider or a hobbyist, you can trust our parts to deliver the strength and precision needed for an exhilarating ride.

For more information on our products and services, or to discuss your specific needs, please contact us today. We look forward to helping you achieve the perfect ride with our expertly crafted metal components.