Welcome to Shenzhen Bondao Technology Co., Ltd.

Embracing the Dawn of the Dragon Year: A Vision for the Year Ahead in Metal Component Customization

As we embark on the first work day of the Dragon Year, it's a moment of reflection and anticipation in the realm of metal component customization. With two decades of experience in this dynamic industry, I find myself compelled to delve into the past, dissect our achievements, acknowledge our challenges, and, most importantly, set our sights on the path ahead.

Looking back, the journey has been both exhilarating and demanding. Over the years, we've witnessed remarkable transformations fueled by advancements in materials science, groundbreaking innovations in processing techniques, and the relentless pursuit of excellence in product quality. Our industry has thrived amidst shifting landscapes, adapting to evolving market demands and technological paradigms.

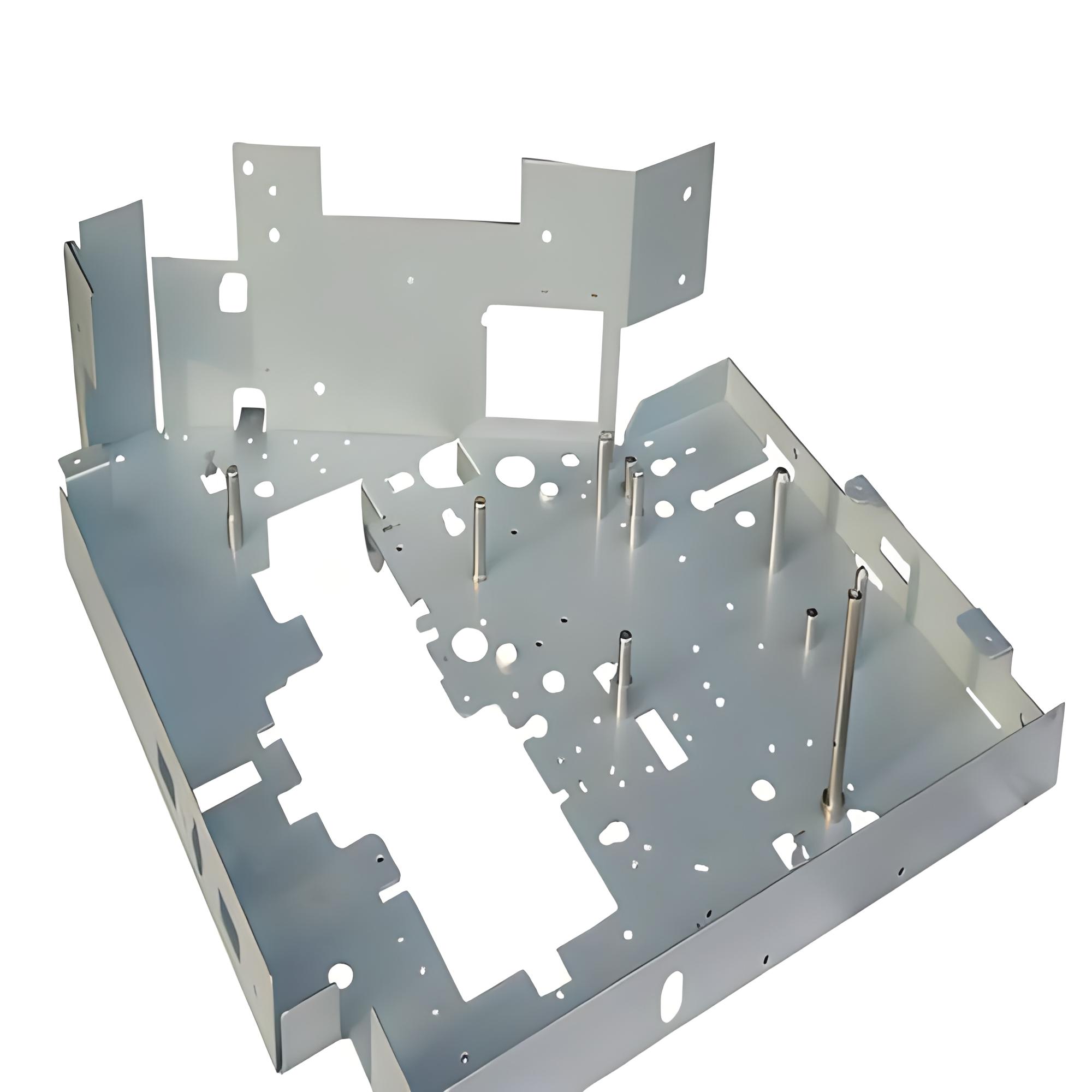

One of the most significant shifts we've observed is the rapid integration of new materials into our manufacturing processes. From lightweight alloys to high-strength composites, the advent of novel materials has revolutionized the way we approach component design and fabrication. By harnessing the unique properties of these materials, we've unlocked new possibilities in product performance, durability, and sustainability.

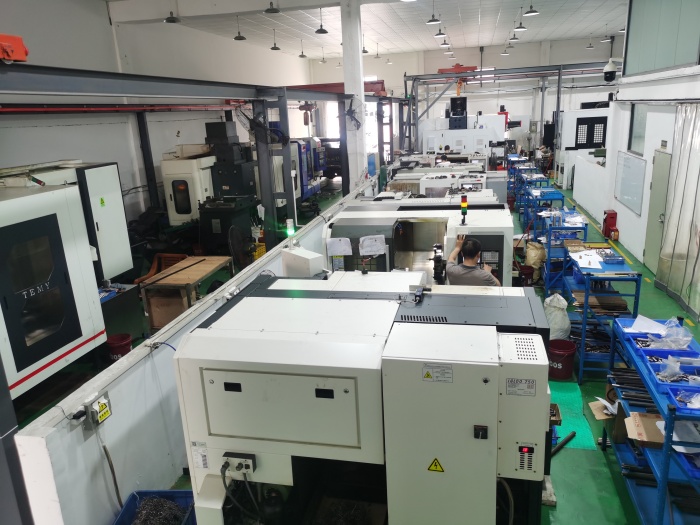

Moreover, the relentless drive for efficiency and precision has spurred continuous refinement in our processing techniques. From traditional machining methods to state-of-the-art CNC technologies, our quest for perfection knows no bounds. With each iteration, we've fine-tuned our workflows, optimized our tooling strategies, and elevated our standards to deliver unparalleled precision and consistency in every component we produce.

However, progress comes with its fair share of challenges. As we navigate the complexities of a rapidly evolving landscape, we encounter obstacles that test our resolve and push us to innovate. Supply chain disruptions, fluctuating raw material costs, and geopolitical uncertainties pose formidable challenges that demand agile responses and strategic foresight.

Nevertheless, it is precisely in times of adversity that opportunities emerge. As we confront these challenges head-on, we uncover new avenues for growth and differentiation. Whether through vertical integration, strategic partnerships, or diversification into emerging markets, we remain steadfast in our commitment to charting a course towards sustainable growth and resilience.

Looking ahead, the future brims with promise and potential. As technology continues to redefine the boundaries of what's possible, we stand at the precipice of a new era of innovation. From additive manufacturing to machine learning-driven optimization, the tools at our disposal are more powerful than ever before.

In the coming years, I envision a landscape where digitalization and automation reign supreme, where data-driven insights inform every decision, and where the boundaries between physical and virtual realms blur. With the advent of Industry 4.0 technologies, we have the opportunity to unlock unprecedented levels of efficiency, flexibility, and customization.

Furthermore, the quest for sustainability will drive profound changes in our industry. From eco-friendly materials to energy-efficient processes, the imperative to minimize our environmental footprint has never been more pressing. By embracing sustainable practices and embracing the circular economy principles, we can not only reduce waste and mitigate environmental impact but also unlock new sources of value and innovation.

In conclusion, as we bid farewell to the past and embrace the dawn of a new year, let us draw inspiration from our collective journey and redouble our efforts towards a brighter, more prosperous future. With resilience, innovation, and a steadfast commitment to excellence, the possibilities are limitless. Together, let us seize the opportunities that lie ahead and forge a path towards a future defined by progress, sustainability, and success.