Welcome to Shenzhen Bondao Technology Co., Ltd.

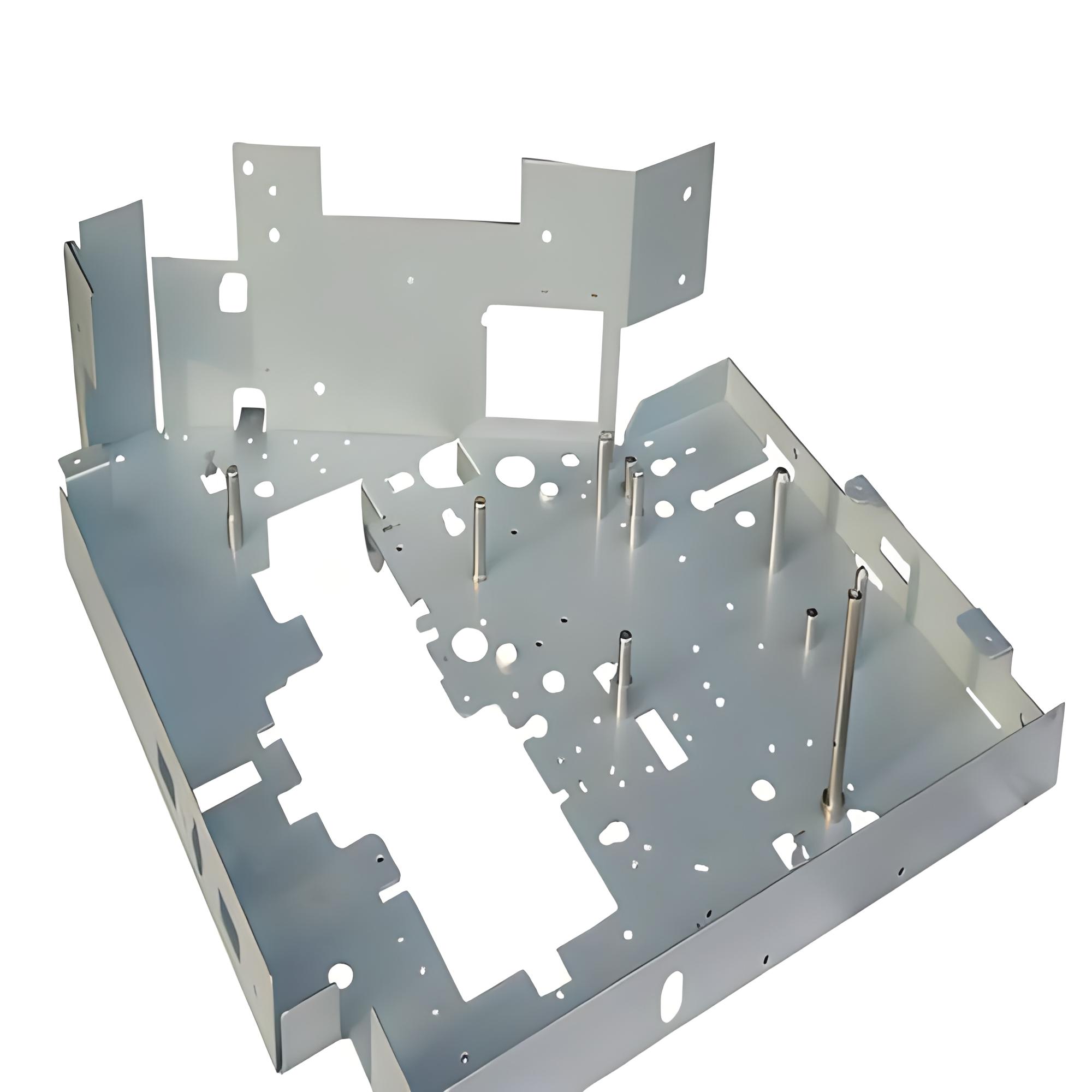

Navigating the Challenges of Aesthetic Defects in Sheet Metal Parts

As a leading manufacturer in the metal parts industry, at Bondao,we understand the importance of both functionality and aesthetics in the components we produce. However, there are instances when sheet metal parts may exhibit minor aesthetic defects that do not compromise their functionality. This blog aims to shed light on how we navigate these challenges, balancing cost, production efficiency, and the end-use performance of our products.

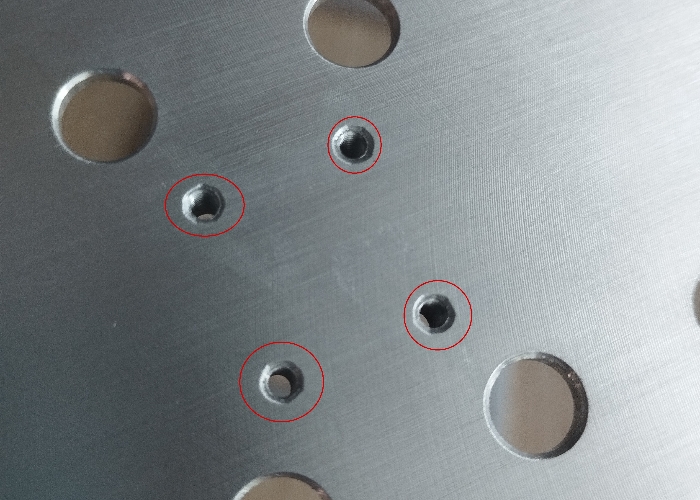

The Reality of Aesthetic Defects

In the world of sheet metal fabrication, achieving perfection in every aspect of a part is an ongoing challenge. Despite rigorous quality control processes, minor imperfections can occur. These aesthetic defects, such as surface scratches, minor dents, or discoloration, often arise during various stages of production, including cutting, bending, welding, or finishing.

Cost Considerations

Addressing every minor aesthetic defect to achieve a flawless appearance can significantly increase production costs. These costs can stem from additional labor, extended production times, and the use of higher-grade materials or more intensive finishing processes. As a result, the final product's price may rise, impacting the competitiveness of our offerings in the market.

From a cost-management perspective, it is crucial to assess whether the added expense of perfecting the aesthetic aspects is justifiable, especially when the primary function of the part remains unaffected. By strategically managing these costs, we can offer more competitive pricing to our customers without compromising on the part's performance.

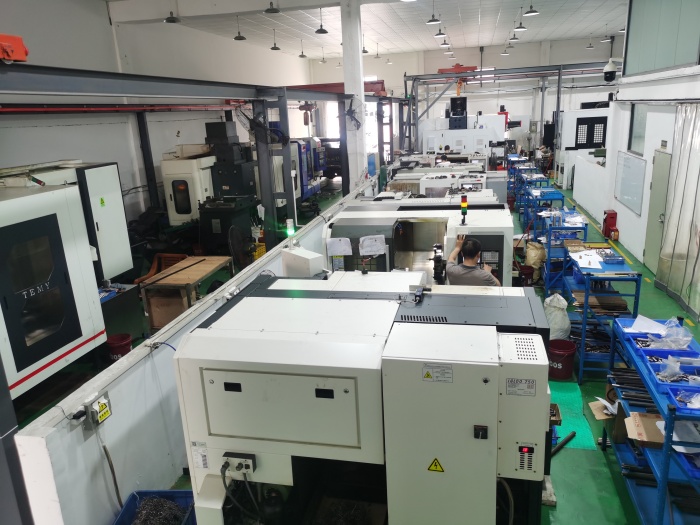

Production Efficiency

Striving for aesthetic perfection in every sheet metal part can also hinder production efficiency. The additional time and resources required to eliminate minor cosmetic imperfections can slow down the manufacturing process. This delay can have a cascading effect, impacting delivery schedules and overall productivity.

Our goal is to maintain a balance between aesthetic quality and production efficiency. By setting realistic standards for minor aesthetic defects that do not impact functionality, we can streamline our manufacturing processes, reduce lead times, and ensure timely delivery of high-quality parts to our customers.

Functional Performance

The primary purpose of any sheet metal part is to perform its intended function reliably. In many applications, the functional performance of the part is paramount, while aesthetic considerations are secondary. For instance, internal components of machinery or industrial equipment may not require a flawless appearance as long as they meet the required performance standards.

By focusing on the functional integrity of our parts, we ensure that they meet or exceed performance expectations. This approach allows us to prioritize the aspects that matter most to our customers—durability, reliability, and precise functionality.

Communication and Customer Collaboration

Transparency and communication with our customers are vital when addressing aesthetic defects. We believe in collaborating closely with our clients to set realistic expectations regarding the appearance of sheet metal parts. By providing clear information about the nature of any aesthetic defects and their impact (or lack thereof) on functionality, we help our customers make informed decisions.

Additionally, we are committed to working with our customers to identify critical areas where aesthetics are a priority and where functional performance takes precedence. This collaborative approach ensures that we deliver products that meet our clients' specific needs and preferences.

Conclusion

As a metal parts manufacturer,At Bondao,we are dedicated to delivering high-quality products that meet the functional and aesthetic requirements of our customers. While minor aesthetic defects in sheet metal parts may occur, we strive to balance cost management, production efficiency, and functional performance to provide the best value to our clients.

We invite our customers to engage with us openly, discuss their specific requirements, and work together to achieve the perfect balance between aesthetics and functionality. Through collaboration and continuous improvement, we aim to meet and exceed the expectations of our valued clients in every project we undertake.