Welcome to Shenzhen Bondao Technology Co., Ltd.

Enhancing Precision and Efficiency: The Impact of CNC Machining for Metal Parts

In the realm of metal fabrication, precision and efficiency stand as pillars of success. Among the array of manufacturing techniques available, CNC machining reigns supreme for its unparalleled accuracy and reliability. Let's delve into the world of CNC machining for metal parts and explore its transformative impact on modern industrial processes.

Unveiling CNC Machining

CNC (Computer Numerical Control) machining represents a pinnacle of technological advancement in metalworking. Unlike conventional machining methods, which rely heavily on manual intervention, CNC machining operates through computerized commands, ensuring meticulous control over every aspect of the manufacturing process.

Precision Redefined

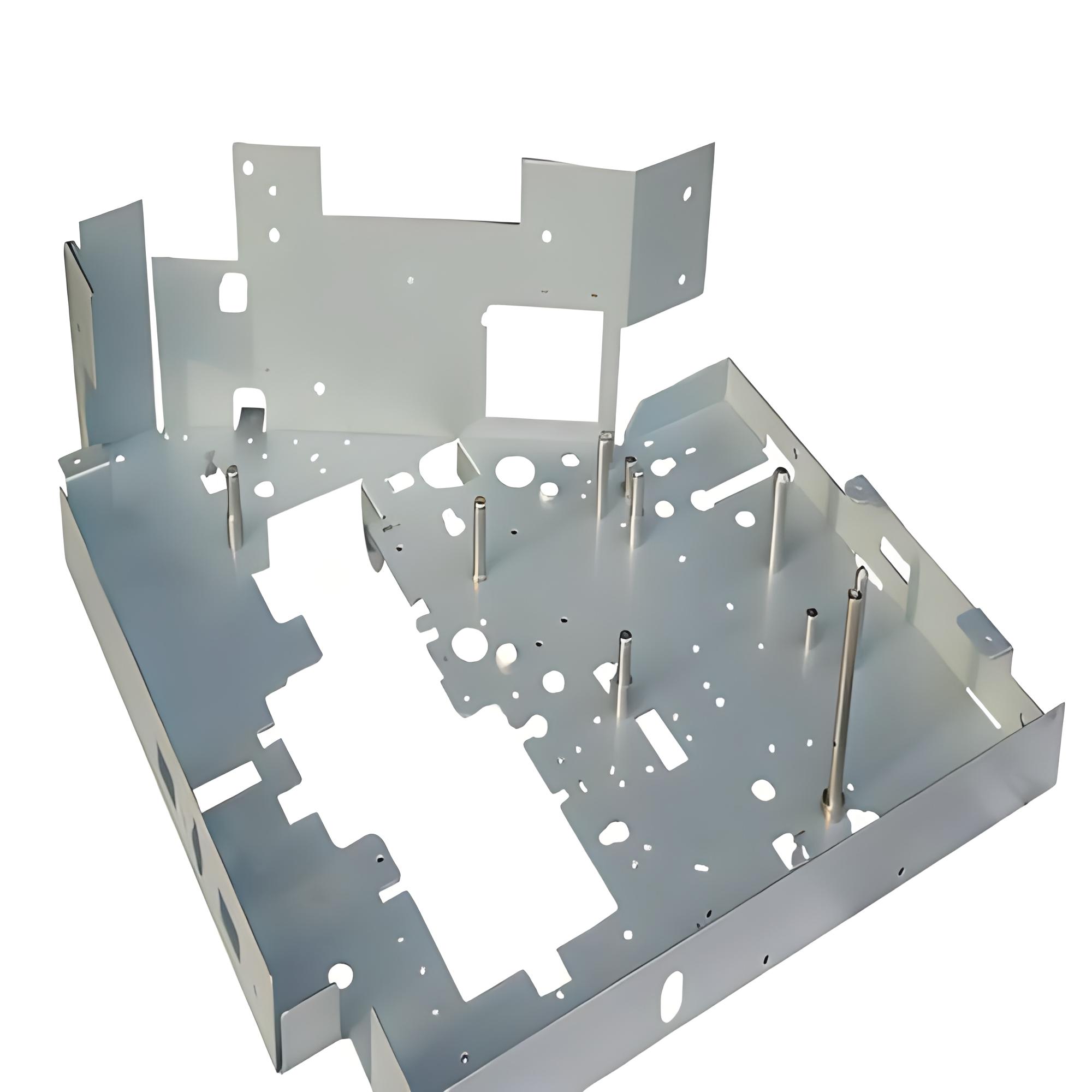

At the heart of CNC machining lies its ability to achieve precision beyond human capability. Utilizing sophisticated software programs, CNC machines meticulously carve intricate designs and geometries with microscopic accuracy. This level of precision ensures consistency across large production runs, minimizing errors and maximizing quality.

Versatility in Material Selection

One of the most remarkable features of CNC machining is its versatility in handling a wide range of metals. From aluminum and stainless steel to exotic alloys, CNC machines adapt effortlessly to the unique properties of each material, delivering superior results across diverse applications. Whether crafting aerospace components or medical implants, CNC machining offers unparalleled versatility to meet the most stringent requirements.

Efficiency Unleashed

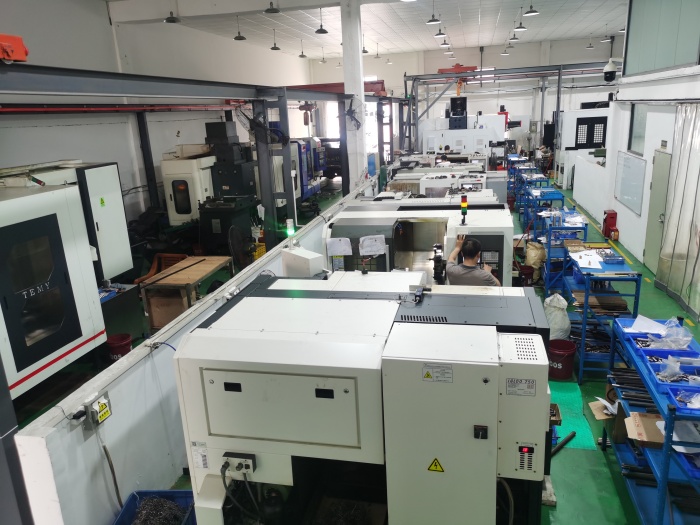

In addition to precision, CNC machining excels in efficiency, streamlining production processes and reducing lead times. With automated tool changes and optimized cutting paths, CNC machines operate with unparalleled speed and consistency, enabling manufacturers to meet tight deadlines without compromising on quality.

The Dawn of Innovation

As technology continues to evolve, so too does the landscape of CNC machining. Advancements in automation, robotics, and artificial intelligence are revolutionizing the capabilities of CNC machines, ushering in a new era of efficiency and innovation. From lights-out manufacturing to real-time monitoring, the future of CNC machining holds boundless possibilities for enhanced productivity and performance.

Conclusion: Shaping the Future of Metal Fabrication

In the competitive arena of metal fabrication, precision and efficiency reign supreme. With CNC machining at the helm, manufacturers can unlock new levels of precision, versatility, and efficiency, empowering them to stay ahead in a rapidly evolving industry landscape.

Embrace the power of CNC machining and embark on a journey of innovation and excellence in metal fabrication.

At Bond, we specialize in CNC machining for metal parts, delivering superior quality and precision with every component we produce.