Welcome to Shenzhen Bondao Technology Co., Ltd.

Advancements in Automotive Metal Parts Production: Exploring Cutting-Edge Processes

In the dynamic landscape of automotive manufacturing, the production of metal parts stands at the forefront of innovation and precision engineering. As the automotive industry continues to evolve, the demand for high-quality metal components has surged, driving manufacturers to explore cutting-edge processes and technologies to meet the evolving needs of the market.

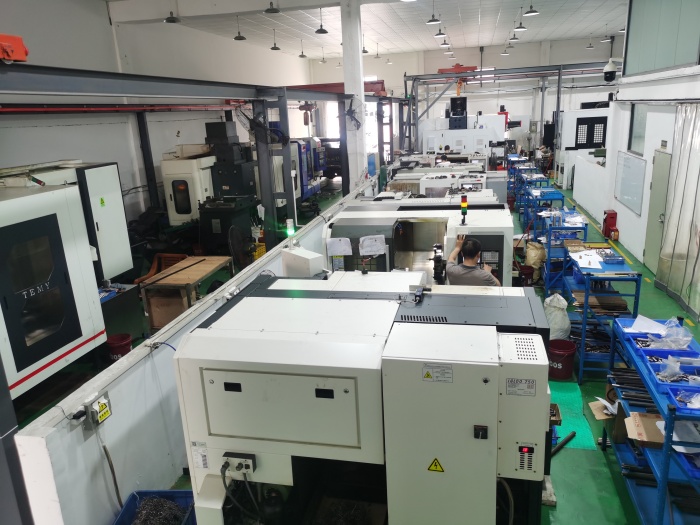

At Bond, we pride ourselves on our commitment to excellence and our relentless pursuit of innovation in automotive metal parts production. With a focus on quality, efficiency, and reliability, we leverage advanced machining techniques and state-of-the-art equipment to deliver superior metal components that exceed industry standards.

One of the key aspects of automotive metal parts production is precision machining, which involves the use of Computer Numerical Control (CNC) technology to achieve unparalleled accuracy and consistency in component manufacturing. By employing CNC machining processes, we can produce complex geometries and intricate designs with remarkable precision, ensuring optimal performance and reliability in automotive applications.

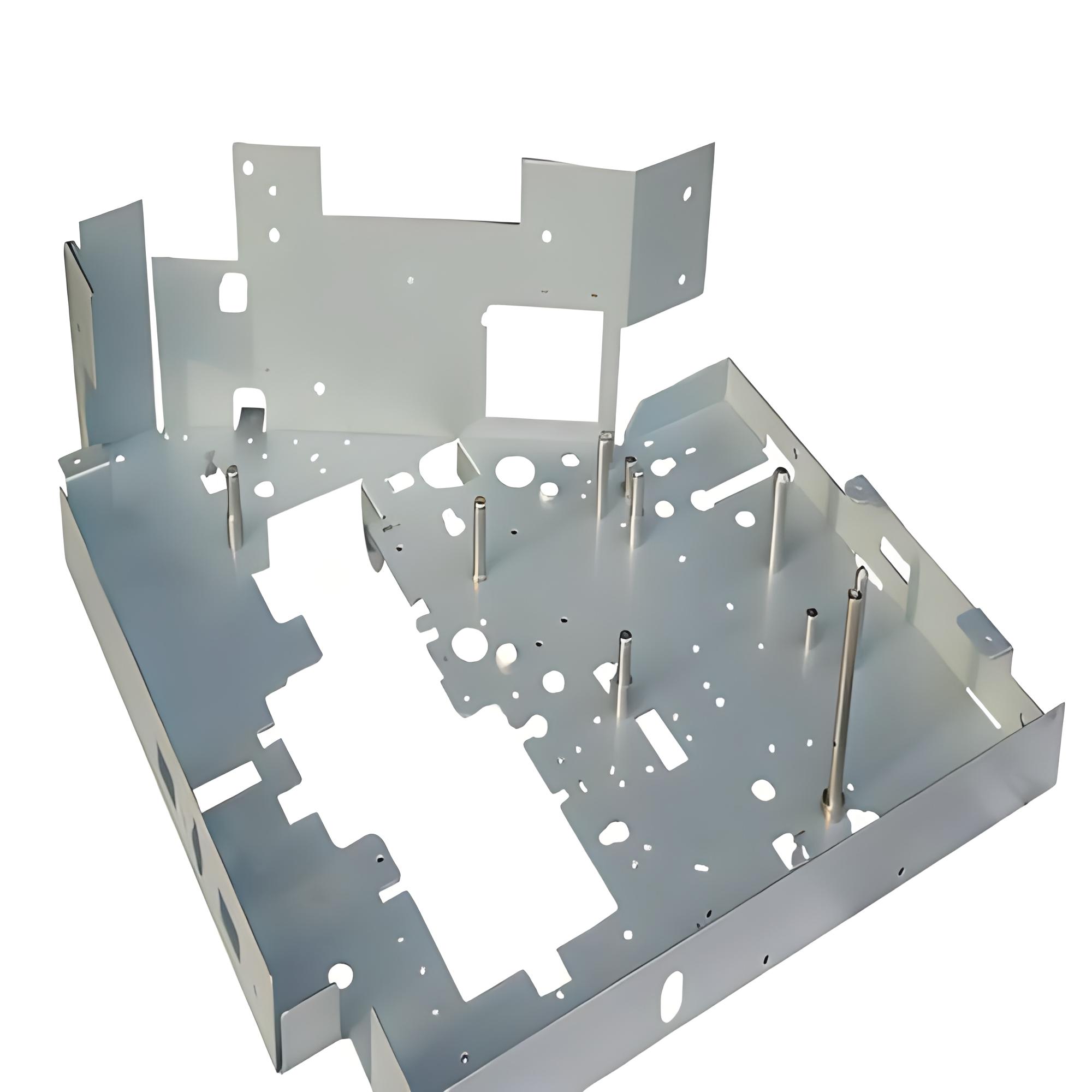

In addition to CNC machining, we also utilize a variety of advanced manufacturing processes such as metal stamping, die casting, and injection molding to create a wide range of automotive components. Metal stamping allows us to efficiently produce high-volume parts with tight tolerances, while die casting enables the production of lightweight and durable components ideal for automotive applications. Meanwhile, metal injection molding (MIM) techniques offer versatility and cost-effectiveness in producing intricate metal parts with complex shapes and features.

Furthermore, surface treatment and finishing play a crucial role in enhancing the functionality and aesthetics of automotive metal parts. Our state-of-the-art surface treatment facilities enable us to apply various coatings, platings, and finishes to protect against corrosion, improve wear resistance, and enhance visual appeal. From powder coating to electroplating, we offer a comprehensive range of surface treatment options to meet the diverse requirements of automotive manufacturers.

Quality control is paramount in automotive metal parts production, and we employ rigorous inspection protocols and quality assurance measures to ensure that every component meets the highest standards of performance and reliability. Through advanced metrology tools and non-destructive testing techniques, we meticulously inspect each part to detect any defects or deviations from specifications, thereby ensuring product integrity and customer satisfaction.

As the automotive industry continues to embrace advancements in materials science and manufacturing technologies, the future of automotive metal parts production holds immense promise. From lightweight alloys to advanced composites, manufacturers are constantly exploring innovative materials to improve fuel efficiency, reduce emissions, and enhance vehicle performance.

In conclusion, automotive metal parts production represents a cornerstone of the automotive industry, driving innovation, performance, and reliability in modern vehicles. At [Your Company Name], we remain at the forefront of this exciting field, leveraging cutting-edge processes and technologies to deliver superior metal components that power the vehicles of tomorrow.

With a relentless focus on quality, precision, and innovation, we are committed to shaping the future of automotive manufacturing and exceeding the expectations of our customers worldwide.

For inquiries about our automotive metal parts production capabilities, please contact us today.